Only released in EOL distros:

Package Summary

Hardware testing tools and utilities. Willow Garage use only.

- Author: Maintained by Kevin Watts

- License: BSD

- Source: svn https://code.ros.org/svn/wg-ros-pkg/stacks/wg_hardware_test/trunk

Overview

The WG Hardware Test Systems performs most production testing for the PR2, assemblies and components. Tests for individual motors, PCB's and batteries are tested through test procedures by the EE department.

Qualification

The WG Qualification system performs acceptance tests of PR2 mechanical assemblies and devices. Components are individual qualified at different stages during the assembly and integration process.

Burn-In Testing

Burn in tests are designed to screen components for assembly defects. All PR2 mechanical assemblies undergo a component level burn in before they are integrated onto the completed robot.

Burn in tests are supervised by the Test Manager system.

Logging and Analysis

Test records are logged in the WG Inventory system. Test records include the timestamp of each log, the completed test, and any notes from operators.

Analyzing Test Data

Data from qualification tests, including historical measurements, historical yield, and testing parameters, can be analyzed and graphed. See the wgtest_data_analysis package for more information.

Diagnostic Logs

Diagnostic logs from all tests are recorded during qualification and burn in. These logs are recorded in the /hwlog directory during testing, and copied to WG servers daily.

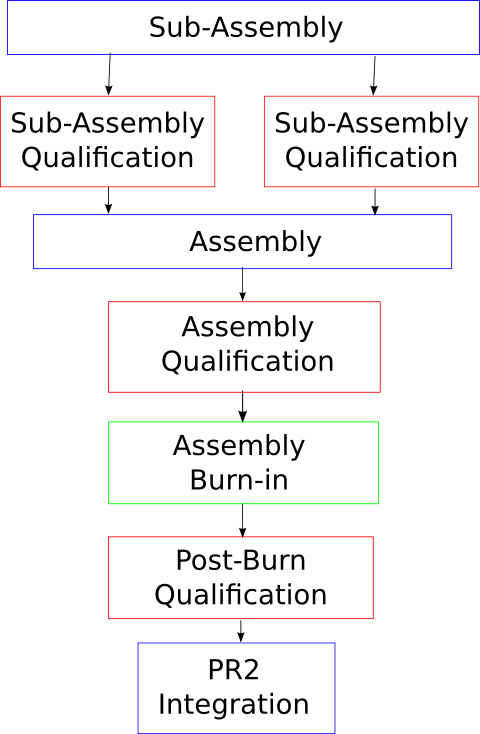

Production Test Flow

All "Qualification" steps are done with the qualification system.

The "Burn In" step is done with Test Manager.

Report a Bug

<<TracLink(wg-ros-pkg wg_hardware_test)>>